AM Feasibility Software

A global manufacturer of trucks, buses and construction equipment contacted Ivaldi as advisors in the implementation of 3D printing in their workflow, a software proposition was made in a week as part of the solution.

Mar 2020

UX/UI Designer

UI Design / Prototyping / Problem Analysis

Tools

Figma / Podio / Google Suit

3D Printing status

As 3D printing technologies improves, many Original Equipment Manufacturers (OEMs) see the potential to manufacture on site, reduce inventory levels and bring back previously obsolete spare parts.

But with so many types of 3D printing technologies, materials and suppliers, many questions arise.

• What is the right path to take?

• Are the offered materials good enough?

• Do we have enough information to digitize the part?

• How do you know when it makes sense to print a part or manufacture it through traditional methods?

The Problem

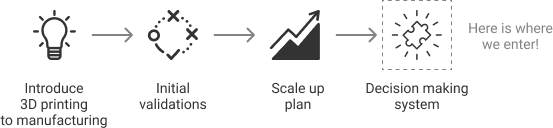

Our client, a global renown automotive OEM has decided to implement 3D printing for their spare parts service and have began printing some of their products to know the process and limitations.

After positive results the operation was scaled up, and as this transform from a Research & Development project to a full scale operation, it's crucial to have a robust decision-making system, so only the parts that make sense continue the process.

In order to validate the feasibility of a part, our client uses a commercial grade spreadsheet divided in stages with parameters implemented to the best of their knowledge, creating a complex workflow and not user-friendly interface.

Our customer's context

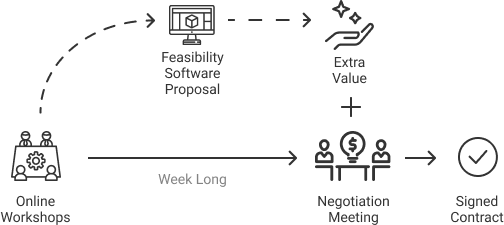

In order to understand their workflow, goals and pain-points a series of online workshops were conducted.

We worked on a software proposal that would take in consideration their current workflow and company needs, as well as Ivaldi’s AM expertise trough a user-friendly interface with a live feed of 3D printings suppliers around the needed location.

As this proposal would be presented during the negotiations meetings we only got a week to create this software solution in a conceptual level, we would focus mainly on the information architecture and roughly design some screens.

Getting to know the problem

We analyzed their current workflow, spending some time getting to know their industry specific concepts and terminology, and the reasoning behind the implementation of all the different parameters that they are taking in consideration.

We detected that several critical parameters were not taken in consideration, also many already considered parameters were not as crucial for the feasibility analysis.

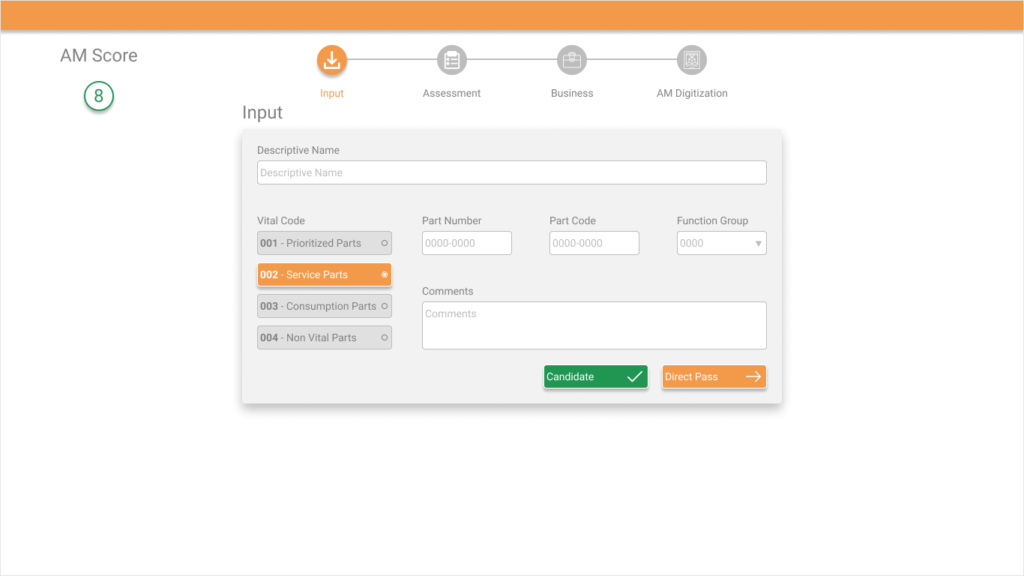

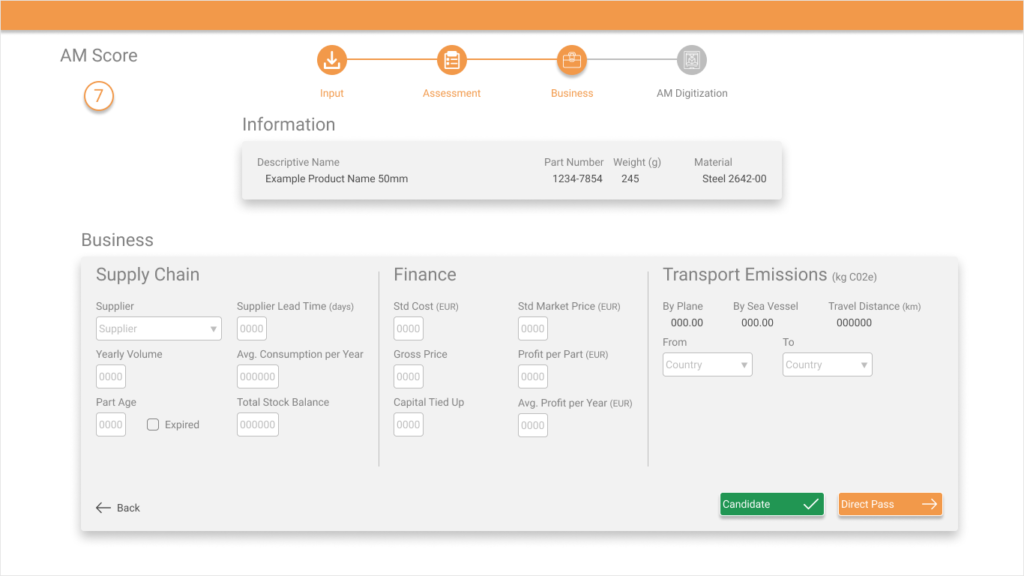

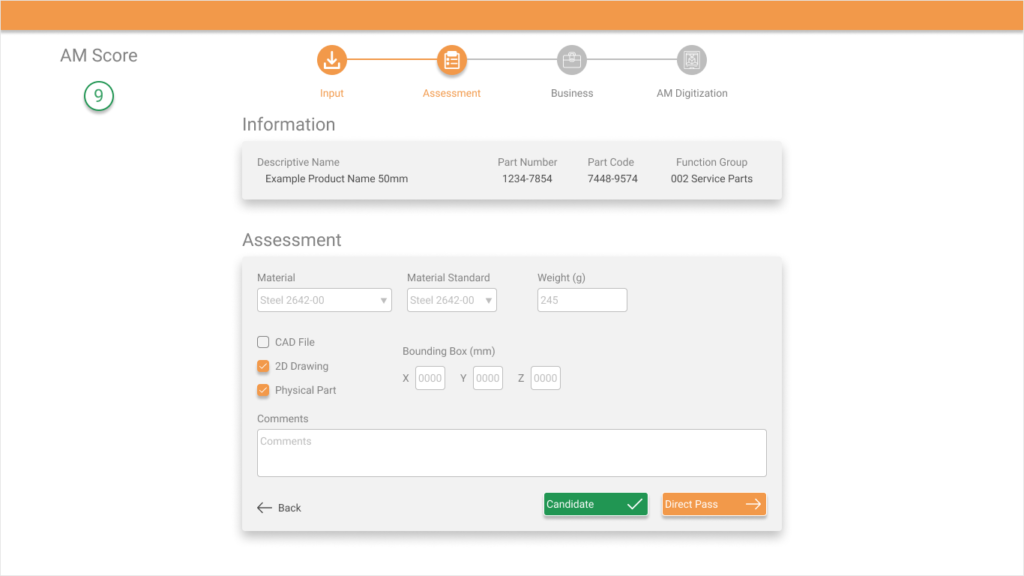

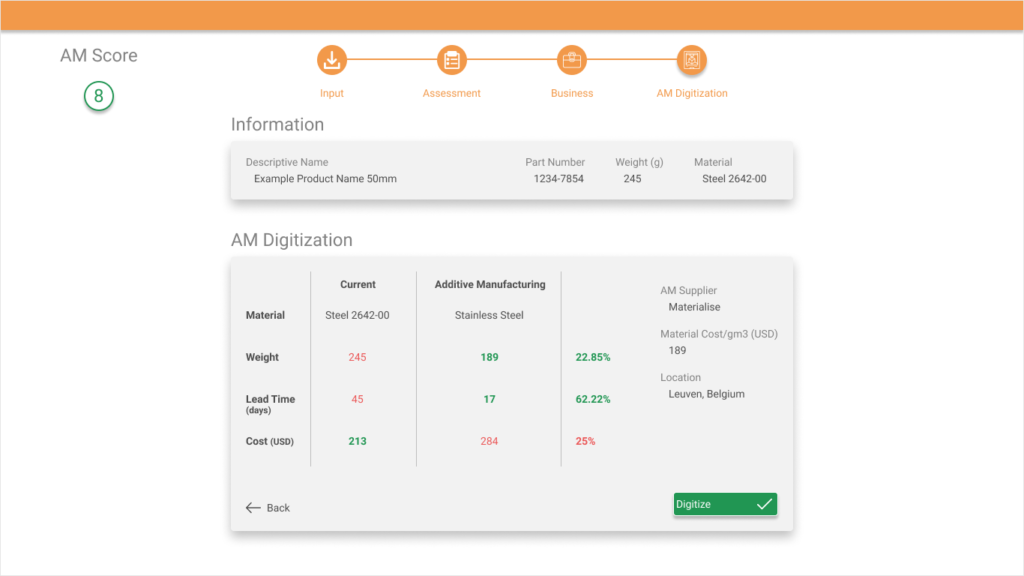

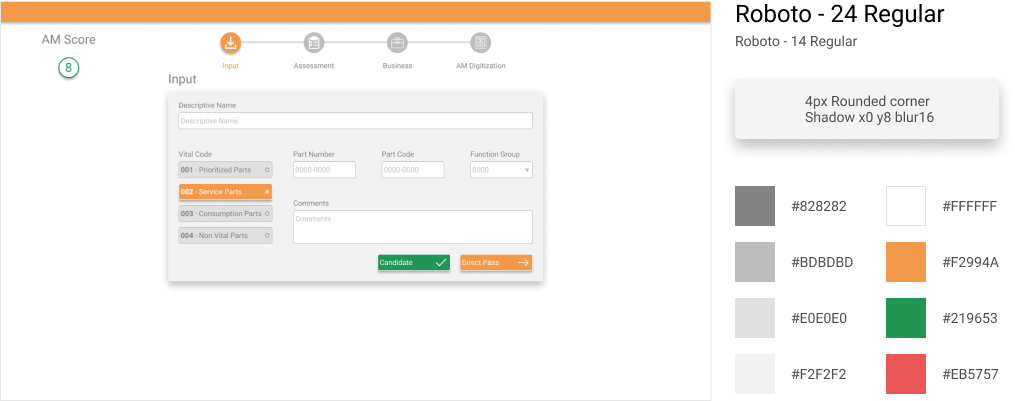

I created a four stage process where each stage focus in a different aspect to determine feasibility.

During each stage, the part will receive a "score" that represents the feasibility of that part in that area.

Because this score system would be based on the local availability of suppliers and their technology, previously failed parts can pass the feasibility test when these suppliers improve their services.

Making the User Interface

I decided to go for a really simple UI design, with high contrast clearly defined input fields and a logical layout.

Modified UI for confidential reasons

Main Pages